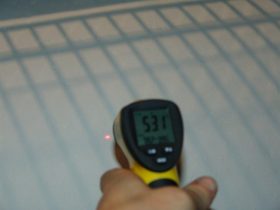

HOT SURFACE COATING is a ceramic based, water-borne insulator designed to insulate in medium temperature situations. HOT SURFACE COATING can be used as a base coat/primer or it can be built up layers for additional protection. HOT SURFACE COATING is specifically engineered to control hot surface temperatures up to 177 °C.

What solution does this offer you?

- HOT SURFACE COATING can be applied over metal, concrete, wood or all surfaces not glazed or containing polypropylene (having no pores)

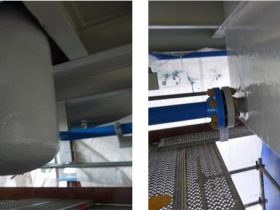

- HOT SURFACE COATING is easy to apply over standard steam pipes, oven wall constructions and other hot surfaces

- HOT SURFACE COATING can be applied to situations where a shut down or drop in temperature is not possible during application

- HOT SURFACE COATING was designed for applications whose temperature exposures falls below that which requires HOT PIPE COATING

Benefits

- HOT SURFACE COATING is easy to apply directly to hot pipes

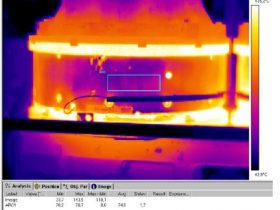

- HOT SURFACE COATING immediately reduces surface temperature and loss of heat

- HOT SURFACE COATING does not absorb moisture or lose insulation value

- HOT SURFACE COATING is safe, non-flammable and non-toxic

- HOT SURFACE COATING can be brushed, rolled or sprayed over any configuration

- HOT SURFACE COATING is lightweight and smooth in appearance

- HOT SURFACE COATING IS USDA approved

HOT SURFACE COATING is a water-borne system using a special acrylic blend with specific ceramic compounds to provide the non-conductive block against heat transfer without depending upon reflectivity. The coating will dry down on a cold surface by evaporation and can be aided in the dry down by adding heat to the environment. If the surface is already heated, the dry-down process will take care of itself without additional steps required.

How does it work

The HOT SURFACE COATING insulation method is very different to the traditional “wrap” insulation materials that only slow down the loss of heat (known as an R-rating or “heat transfer”). The seven ceramic compounds in the HOT SURFACE COATING create a barrier to catch and hold heat on the surface of the unit, e.g. pipe, furnace surface, boiler, etc.

Unlike wraps that use air as the insulation component, the ceramic compounds in the HOT SURFACE COATING resist absorbing heat trying to come off the surface to escape. This traps and holds the heat onto the surface for more effective insulation performance.

Further information

HOT SURFACE COATING was designed for applications whose temperature exposures falls below 177°C and can be applied to metal, concrete, masonry and wood. HOT SURFACE COATING is safe, non-flammable and non-toxic. For more information please read:

HOT SURFACE COATING TECHNICAL SHEET

HOT SURFACE COATING APPLICATION INSTRUCTIONS

HOT SURFACE COATING has been successfully tried and tested throughout the world and has received numerous certificates to substantiate its effectiveness and reliability. For updated SDS and/or further information regarding these different test results please contact us.

HOT SURFACE COATING’s compound structure has proven in the field to offer superior results when compared to traditional “wrap” insulators. Please find below a few selected references from our Global Database intended to show the type of application, solution and markets in which HOT SURFACE COATING has successfully been applied: